Introduction

The energy transition from fossil fuels to electricity poses significant strains on electricity grids and energy availability across Europe. As a consequence, Manufacturing companies are increasingly faced with high energy costs and energy volatility. They need a scalable and flexible solution that helps them reduce costs and increase the energy independence.

Strategies employed:

- Improve decision-making capabilities through advanced production scheduling models and real-time insights.

- Enhance energy efficiency and reduce electrical grid dependency by optimizing the energy mix and scheduling.

- Reduce CO2 emissions and increase use of renewable energy, in alignment with Europe’s sustainability goals.

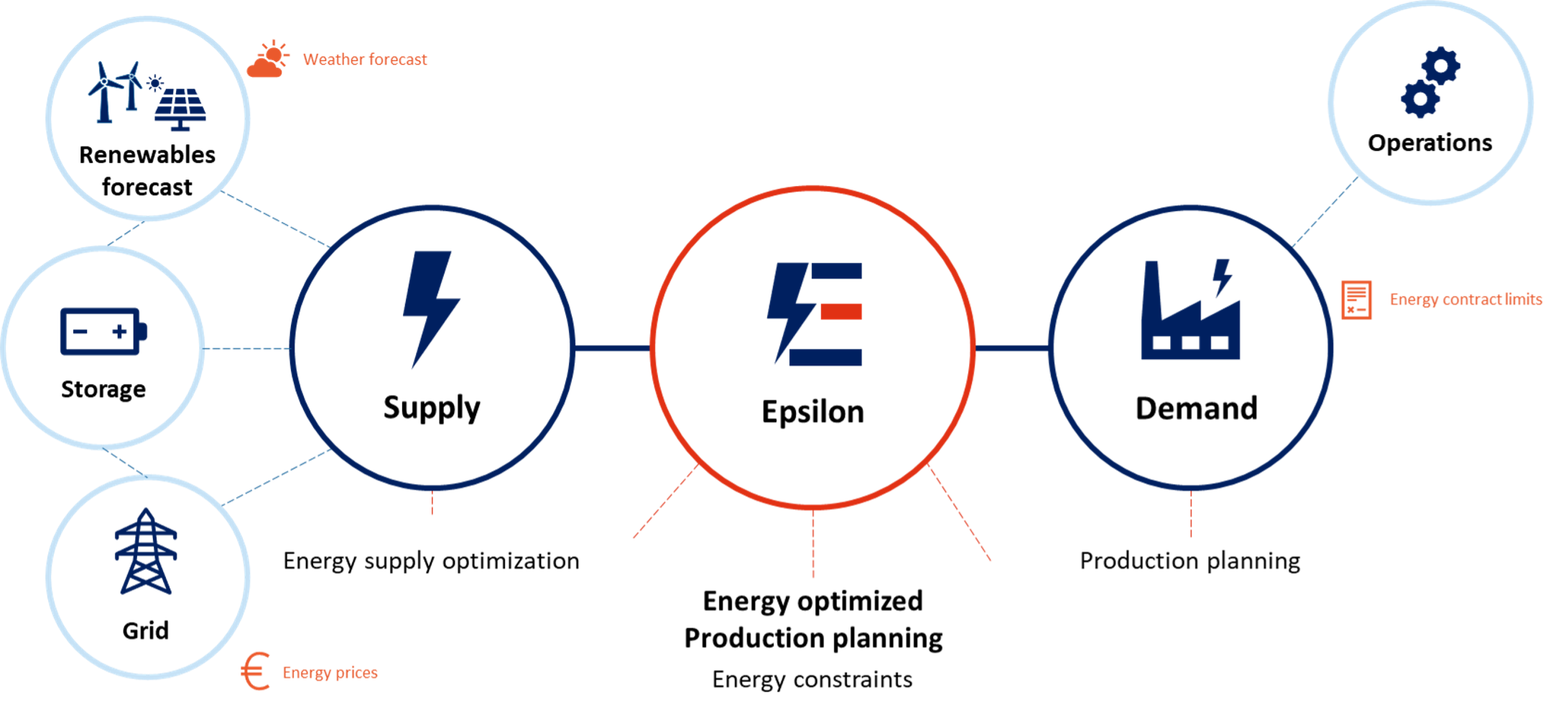

Four elements are at the heart of our solution: